Filtered Intake Uses: Dip Tube Filter, Suction Strainer & more!

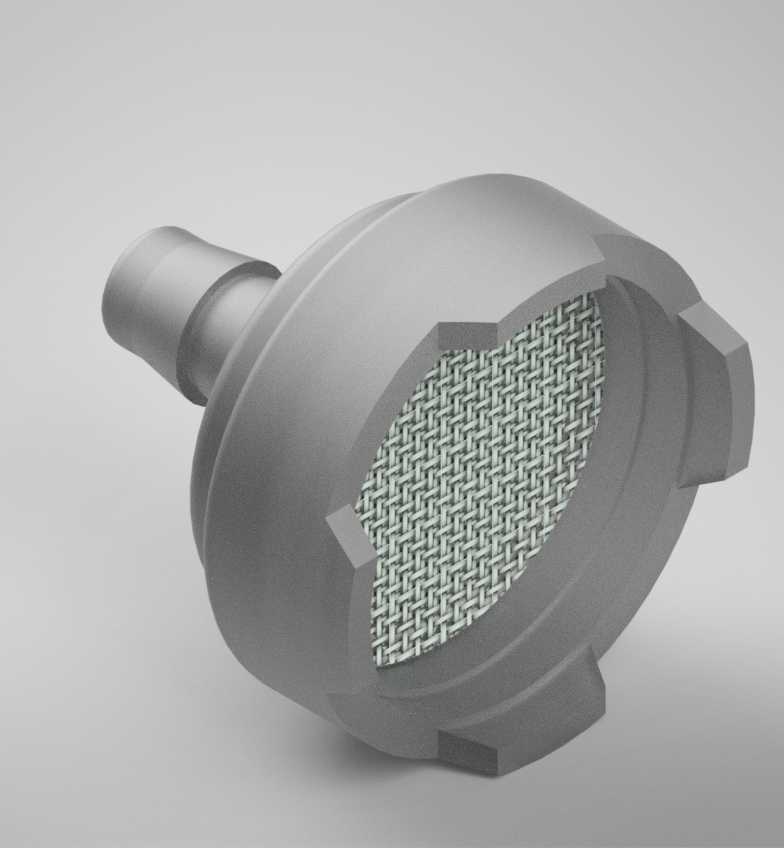

Comments Off on Filtered Intake Uses: Dip Tube Filter, Suction Strainer & more!A filtered intake is a protected entrance for a gas or liquid coming into a system or device. It has a single tube fitting attached to a filter housing or end cap, and an open filter element on the other side. Standoff geometry on the filter side of the product prevents blockage when pushed up against a flat surface. The product is a small plastic filter that can be a single-use filter, that gets disposed of with the container, or it can be fixed to the device or system and replaced as needed. Different applications of a filtered intake each have their own name for the product. The container can indicate what the filter is called. Dip tube filters are typically used in bottles. Suction strainers and pickup filters are typically used in tanks.

Applications: dip tube filter, suction strainer, pickup filters

What is a Bottle Dip Tube Filter?

A Dip tube filter is meant to be submerged into a liquid and will filter out debris before it enters the system or device. It fits at the end of the dip tubing and prevents contamination from entering the system. The goal of dip tubing is to extract the maximum amount of fluid from a container or bottle. By using a bottle dip tube filter, the system may be designed in a way to hold the end of the filter up against the bottom surface of the container without blocking the flow into the dip tube. Generally, dip tubing is cut to a specific length, relatively stiff, and matched to the container that it is in. Depending on the chemical and container, these design aspects may be critical to comply with § 261.7 Residues of hazardous waste in empty containers.

What is a Suction Strainer?

Dip tube filters and suction strainers are very similar from a functionality standpoint. Suction strainers are also used to “pick up” fluid from the bottom of a container, but might not have a matched tube length and container. Commonly, a suction strainer tube will be longer and softer so that the filter rests on the bottom of the container. This type of application can accommodate a larger variety of containers but may leave more residual fluid in the container.

What is a Pickup Filter?

A Pickup Filter rests in the bottom of a refillable tank and “picks up” fluid. The filter is part of the equipment and is replaced on a maintenance schedule. Examples: Filter pickup in a fuel tank on a small engine. Filter pickup in a window wash container.

How to specify a Filtered Intake

Filter mesh size – Start here!

The first criterion to specify in any filter is the filter mesh size, which determines the particulate size that the system will be protected against. First, determine the minimum particulate size that will have a negative impact on the overall system. Then pick a filter mesh size that is a little smaller. This way, the filter will prevent any particulates from entering the system than might impact the performance.

Tube ID – Match with barb size

Match the bottle dip tube filter with the dip tubing size. A common dip tubing internal diameter (ID) is 1/8″. This can vary depending on the flow rate and viscosity of the fluid in the system.

Flow rate control – Extremely useful in some applications

In some cases, it may be advantageous to integrate a flow restrictor orifice into the filtered intake. This will control the rate at which fluid can be sucked or drawn into the system. We offer a range of sizes to suit your needs, check out our catalog page. It is possible to error-proof the flow rate of a liquid this way. Interested in some examples of how to use an orifice restrictor in your application? Check out this article!

Air Logic’s Filtered Intake

At Air Logic, we make filtered intakes that are used in a range of applications. They are small plastic filters produced in Racine, Wisconsin. Dip tube filters for bottles are the most common. Other applications include pneumatic intake filters for miniature pumps and automatic milk frothers. We work with customers who have unique filter needs and produce solutions for them. We customize features like filter mesh, plastic material, or custom flow rates (orifice restrictors). The color of the product indicated the filter mesh size. The color of the flow restrictor orifice (if included) indicates the flow rate. Check out our Filtered Intake Catalog page!

Air Logic’s Dip Tube Filter is designed to allow the dip tube to be positioned as close as possible to the bottom of the bottle. The stand-offs at the bottom of the filter allow for a flush mount while not restricting flow to the dip tube. Due to this, our design allows for a complete evacuation of the bottle while straining particulates and protecting the system.

Air Logic has experience with a range of filter products. Our filtered intake is ultrasonically welded together on automated equipment for a high-quality bond every time. Lot control is maintained from assembly through delivery to ensure quality.

If you have any questions about this filter or other small plastic filters, please reach out!